A group of engineers who enable the supply of industrial gases to customers in every field. Our technologies support the society we live in.

As shown above, the industrial gases we supply support the production and manufacturing of everything and anything you can see around your life. Our name is not often brought up in society, but we keep working as a “backseat player” of people’s lives, living, and economy to reach a new level of monozukuri by refining our techniques with pride and responsibility in our mind.

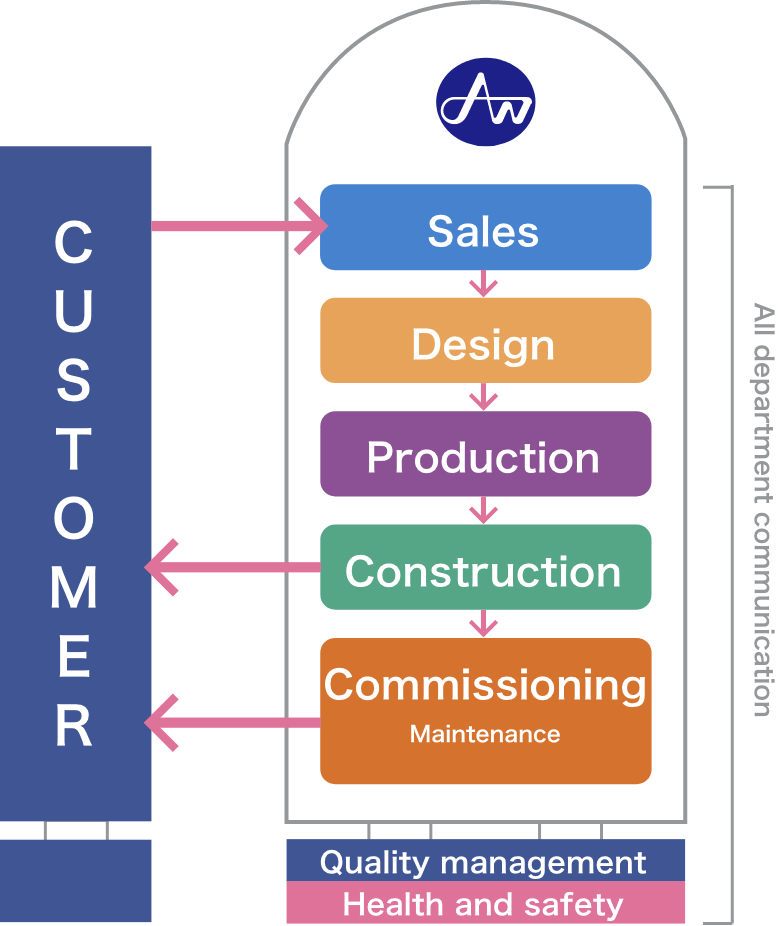

Schematic representation of project workflow

We fulfill stringent technological needs in various industries, train professionals in each field for advanced techniques of plumbing and welding, and develop various types of high-quality piping installation techniques as well as technologies and construction methods for reducing environmental burdens, proactively working on the establishment of novel circulation technologies.

We have established a seamless, coherent monozukuri system with design, manufacturing, installation, quality control, and maintenance all within one company.

We listen to our customers’ needs and demands and promote communication among design, installation, and production divisions as a project facilitator. From collection of the latest information to communication with engineers, we need to have a wide variety of knowledge as well a sense of balance.

We are a group of engineers who pursue the highest technological capabilities and possibilities while nurturing our own independence and motivation. We aim to create something unbreakable, attain satisfactory performances, and reduce costs. We don’t always rely on past experiences and know-how, but always aspire for the development of novel technologies and techniques.

Our permanent goal is sustainability of monozukuri that can last 100 years. The strength of our company is quick responses to customers, which can only be realized from our coherent monozukuri system. As a division responsible for production, we have established an organizational climate where we have persistence to our technologies, are never satisfied with the status quo, and consistently challenge improvement and enhancement.

We are responsible for safely control-related operations for our customers, subcontractors, and own company, including various tests related to schedule management and quality of field works, on-site observation of tests, and KY (Kiken Yochi, or risk prediction) activities with risk assessments. We are proactively implementing new technologies, seeking higher-quality, lower-cost installation methods, such as shorter construction periods and fewer construction workers.

We are responsible for product quality inspections and purity tests of gases supplied from our facilities to our customers. Our goal is to maintain the quality of our products in compliance with related legislative measures and internal company standards. As the company manufactures and supplies various kinds of products, our division is unique in that each member is responsible for a wide range of operations, requiring each individual’s judgment of the situation and ingenuity.

We are aiming to create a system for improving safety awareness both from the top and in the field, including formulating plans and systems related to safety and health during construction. Specifically, our tasks include holding examination meetings for construction plan documents and verification of construction plans. We not only educate people at meetings but also implement safety campaigns and raise awareness in the field.

We are responsible for everything related to safety and stable supply of generated gases, including plant facility checks, analyses of concentration and composition of generated gases, and facility checks after delivery. As we work on missions in such environments where 24-hour operations are required and stoppage is not allowed, we are required to have a wide range of knowledge, thorough plans and preparation, and flexibility to deal with unexpected events.